This site

is mobile

responsive

Rare-earth elements (REEs) are a group of 17 chemical elements of lanthanide series within the periodic table. Despite their abundance in the earth’s crust, their geochemical properties lead to low concentrations, making mining less viable. Nevertheless, despite the challenge in harvesting these materials, one may wonder why industry players flock towards such rare elements. This article aims to shed light on how REE is viewed to be a strategic material in Malaysia.

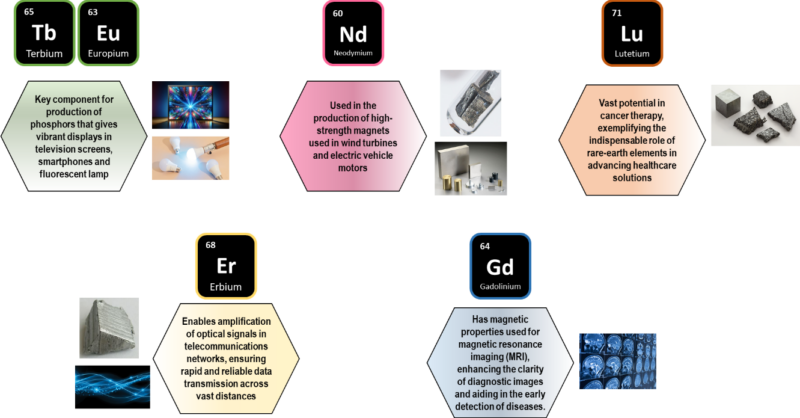

REEs commonly categorised as light rare earth metals and heavy rare earth metals, have gained immense popularity for its usage in various segments as illustrated below. In a nutshell, REE’s demand boom is attributed to emerging technologies and advancement in the medical, automotive, electronics, healthcare and clean sectors.

As REEs are not geologically found in their isolated element form, separation and purification are required. This is typically performed on rare earth oxides through extensive and resource-intensive processing involving mechanical, flotation, chemical, and thermal steps.

There are two primary methods for extracting REEs:

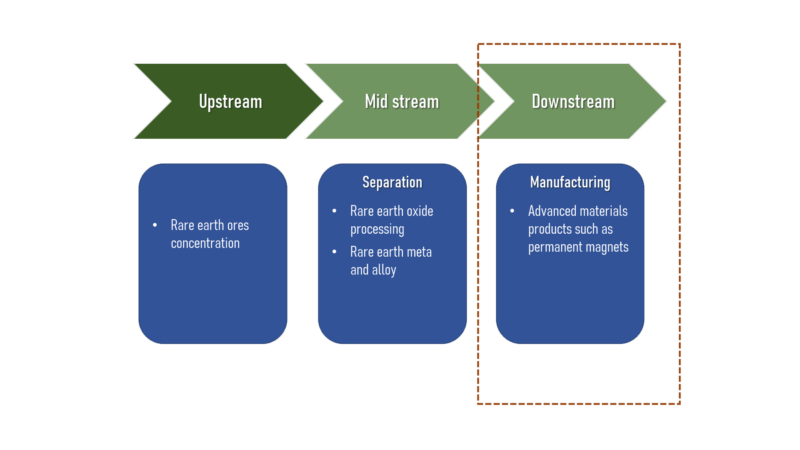

Estimated to reach USD 9.38 billion by 2028 with a CAGR of 5.4%, the Asia Pacific region is observed to continue leading the market share. The REE supply chain, currently dominated by the People’s Republic of China (PRC) which accounts for approximately 85% of the global supply, followed by Australia, has a fairly straightforward value chain. The value chain consists of upstream activities, which involve mining and cracking, and midstream and downstream processes, which become integral building blocks of super magnets used in smartphones and electric vehicles.

Malaysia, home to the largest single light rare separation facility in the world1 through Lynas, records significant exports recognised globally.

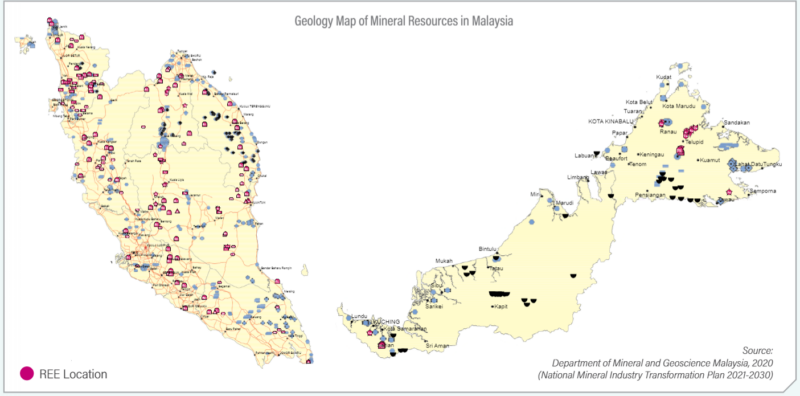

Recently, Malaysia has gained more prominence due to its REE reserves. Malaysia’s domestic rare earth minerals is seen to be a step forward as the world seeks to reduce reliance on China. The abundance of medium and heavy REE in ion adsorption clay ores makes this resource particularly attractive2. IAC3 is supposed to have a high REE content but with lower percentages of radioactive elements like Thorium (Th) and Uranium (U). The country’s reserves, particularly found in Terengganu, Kelantan, Pahang, Perak, and Kedah are home to valuable deposits of rare-earth minerals such as Neodymium (Nd), Dysprosium (Dy), and Praseodymium (Pr). These elements are vital components in the manufacturing of powerful magnets, essential for renewable energy technologies and electric vehicle motors.

The vast usage along with continuous research on optimisation of sustainable extraction, provides promising opportunities for Malaysia’s IAC-REEs. The New Industrial Master Plan (NIMP) 2030 has identified the potential of REE and aims to tap into its 18.2 million tonnes of non-radioactive RE reserves by year 2030. This is valued at RM747.2 billion and has the potential to attract RM100 billion worth of investments creating 4,000 job opportunities4.

While it may seem with these opportunities, Malaysia has made headway, there are however mammoth of challenges that have posed limitations for the country from gaining its grounds. The country has an arduous task in identifying players with technology that can ensure safe and sustainable mining. Identifying the right players while ensuring the nation’s natural resources are not overexploited is a daunting balancing act creating an obvious void in the upstream segment of the value chain.

A different scenario compared to the upstream segment, the mid-stream has been thriving in Malaysia. The country’s capability in the midstream section of the REEs value chain, coupled with its matured manufacturing sectors, opens prospects into the downstream section which focuses in manufacturing of advanced materials. This prospect, specifically the manufacturing of super magnets, links aptly with the ASEAN region’s EV ecosystem which indirectly bolsters Malaysia’s position as ASEAN’s base for a complete supply chain for EV.

Source: MIDA

Recognising REEs as a game changer for Advanced Materials Industry, the Government of Malaysia has outlined long-term strategies for a sustainable development increasing competitiveness and resilience. However, these strategies are only possible with active participation by the private sector, including both foreign and domestic investors. MIDA, as the Government’s principal investment promotion agency is committed to facilitate investments in REE and its downstream advanced materials.

To know more, please contact the Chemical and Advanced Material Industries Division at https://www.mida.gov.my/staffdirectory/chemical-and-advanced-material/.

1 National Advanced Materials Technology Roadmap 2021-2030, MOSTI

2 Balancing economic growth and environmental protection: A sustainable approach to Malaysia’s rare-earth industry, Eli Syafiqah Aziman, Aznan Fazli Ismail, Muhammad Abdullah Rahmat

3 Ionic absorption clay deposits are abundantly found in regions such as Perak and Pahang

4 National Advanced Materials Technology Roadmap 2021-2030, MOSTI