This site

is mobile

responsive

Materialise is a pioneer in the 3D printing industry, with over three decades of experience in this groundbreaking field. With an extensive range of software solutions and 3D printing services, Materialise provides a strong foundation for the industry. Its adaptable and open-platform solutions offer unparalleled opportunities for players in various sectors, such as healthcare, automotive, aerospace, art and design, and consumer goods, to create innovative 3D printing applications that aim to improve the world and promote well-being. Headquartered in Belgium, Materialise boasts a global presence, with branches located across the globe.

Materialise’s global presence is further bolstered by its Asia-Pacific hub, Materialise Sdn. Bhd., which serves as a center for sales, research and development (R&D), and medical services. Housing a talented team of over 200 dedicated innovators, Materialise Sdn. Bhd. has been a vital part of the company’s growth since its inception in 2000. Materialise Sdn. Bhd. software solutions for additive manufacturing (AM) cater to the healthcare and industrial sectors across Southeast Asia, South Korea, India, Australia, and New Zealand.

Materialise has chosen Malaysia as the hub in the region because Malaysia is located in the central of ASEAN, with easy access to neighbouring countries. This is an important factor in promoting the company’s products and services in the region. Apart from having the strength in technology, Malaysia also has an abundance of talented engineering and technology professionals which can help increasing the potential of adopting new technologies such as the additive manufacturing in Malaysia.

Materialise software solution and medical services:

1) Additive Manufacturing Software for industry

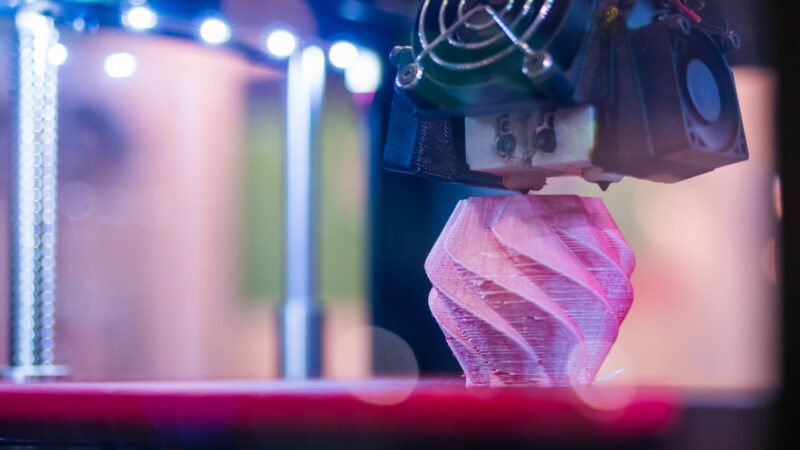

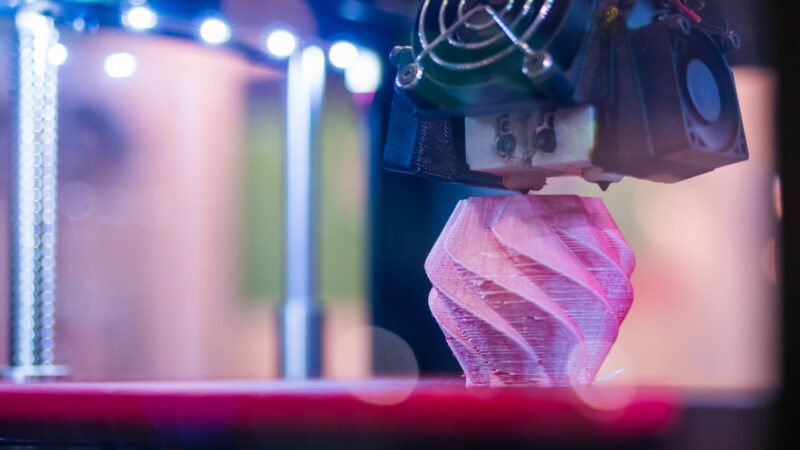

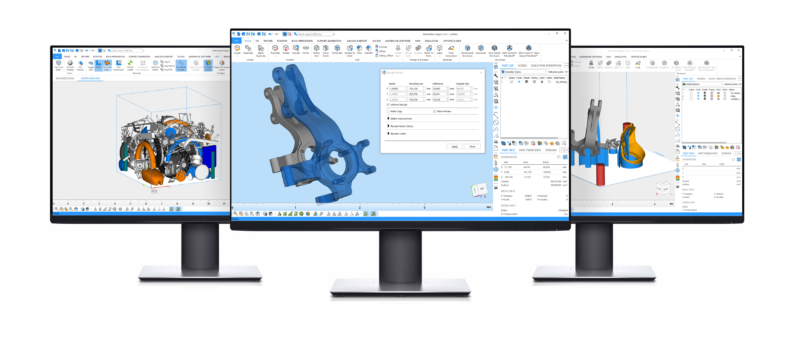

Materialise Software provides companies with a platform of software tools that manage and control the 3D printing process more efficiently, allowing them to meet the highest standards of the most demanding industries. At the heart of this platform is the Materialise Magics 3D Print Suite which includes design optimisation, industry-leading data and build preparation software for AM production factories. In addition to providing software tools for AM production facilities, Materialise Software also offers advanced software and control systems that bridge the gap between applications and 3D printers.

Materialise Magics 3D Print Suite is an extensive software solution that enables you to manage every step of the additive manufacturing workflow.

These solutions are built on an open architecture, which fosters co-creation and collaboration between different players in the 3D printing and manufacturing eco-system and providing the industry a solid foundation on which to expand and grow. Discover how industries — like automotive, aerospace, and more — are benefiting from Materialise Software solution to improve their productivity in the Additive manufacturing from the following stories:

2) Medical Software and services for Academic research and personalised care

Materialise Medical is a pioneering force in the medical applications of 3D printing, enables researchers, engineers and clinicians to create innovative personalized treatment thatimprove patient care. At the heart of Materialise Medical’s platform is Materialise Mimics Innovation Suite, a flexible and open software platform that serves as the foundation for certified medical 3D printing in both clinical and research settings. Materialise Mimics provides a wide range of tools which enable virtual pre-surgical planning, design and printing of 3D-printed anatomical models and patient-specific surgical guides and implants, giving clinicians the precision and control they need to achieve optimal outcomes.

In terms of services, the company’s in-house team of clinical engineers assists surgeons with 3D virtual surgical planning and customising personalised surgical guides for orthopaedic surgery worldwide. They also collaborate with government agencies, leading industry players, academia, and research institutes to advance the adoption of 3D printing in the Asia-Pacific region through professional training programs and the co-creation of new applications.

3D virtual surgical planning with Materialise clinical engineers

Discover how 3D Planning and Printing technologies accelerate the adoption of personalized care in healthcare through the company’s customer stories:

Advice to other companies considering investing in the 3D printing industry

Over the past thirty years, 3D printing, also known as additive manufacturing (AM), has evolved from a niche technology to a versatile solution that is now used across a broad range of industries. This development has been driven by market leaders and innovators who were able to recognise and build on the nascent potential. AM technology allows for designing parts for function rather than manufacturability, bringing about major added value such as improved part performance thanks to benefits such as part consolidation and complex shape designs, for instance. Driven by the advancement of three essential areas – software, hardware, and innovation powered by people – additive manufacturing enables completely new business models. Mass customisation and personalisation, as well as flexible production processes, become easily attainable, with lower initial investment thanks to shorter iteration rounds. Apart from that, AM has been recognised as an Industry 4.0 technology with the potential to increase supply chain agility by enabling on-demand distributed manufacturing to meet consumer and industrial demand.

Mr. Fried Vancraen

CEO of Materialise

Recently, the Belgium Embassy, in collaboration with Materialise Sdn. Bhd. had conducted an industry dialogue between Materialise founder and CEO Fried Vancraen, and a select group of senior industry leaders, government and trade agencies representative on the topic of advancing business growth with Additive Manufacturing technology in Malaysia.

During the dialogue session, the rise of smart, distributed manufacturing was identified as one of key considerations in the adoption of additive manufacturing. In recent years, global disruptions caused by the COVID-19 pandemic and geopolitical tensions have made manufacturing companies reconsider their centralised production model. With smart digital technologies like AM, manufacturers can shift towards operating through multiple smaller- scale production sites that are located closer to their customers.

That said, despite its undeniable capacity to disrupt traditional value chains, some organisations are still slow to adopt AM. Many leaders and decision-makers face the challenge of the lack of an AM ecosystem and marketplace in the country, which makes it difficult for them to make informed decisions about implementing new technologies. It is therefore crucial for business leaders to partner with the right service providers who can help them identify where and how the technology will add value and drive down the total cost of ownership.

Materialise Sdn. Bhd. strives to work together with local partners and agencies towards creating the ecosystem which support local companies in adopting AM technologies. The company believes that by combining its expertise and knowledge in AM, with a uniquely open data-driven ecosystem will be able to empower companies across all industries to create innovative 3D printing applications, regardless of where they are on their 3D printing journey. In the same vein, the company’s approach – which includes co-creation, consultancy, training, services, and products – is adaptable to all levels of 3D printing adoption.

The event was attended by representatives from MIDA, Malaysia Automotive, Robotics & IoT Institute (MARii), SIRIM, Aerospace Malaysia Innovation Centre (AMIC), Institute of Clinical Research (ICR) and industry players such as Petronas Technology Venture, Dyson Manufacturing and BISELL.