This site

is mobile

responsive

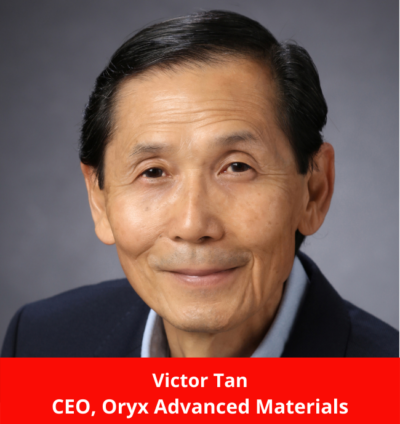

Oryx Advanced Materials is a leading US-based manufacturer of high purity, high-performance complex alloys used in creating thin films for a variety of applications, including magnetic storage and photovoltaic (PV) solar cells. The company’s team of material scientists and engineers are experts in the fields of vacuum induction melting and powder metallurgy.

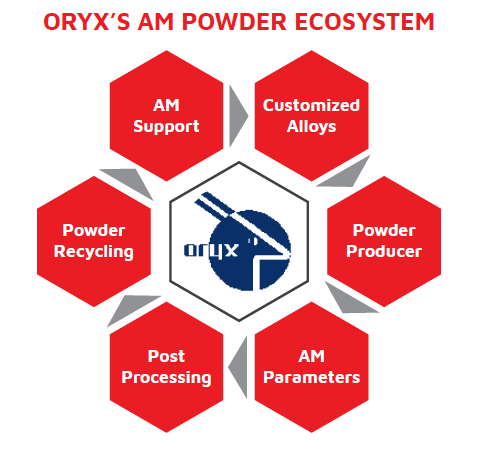

Oryx applies this expertise to educate and assist manufacturers that are considering the transition to utilising additive manufacturing (AM), commonly known as 3D printing. Oryx has created an ecosystem for this technology to empower manufacturers in the adoption of AM.

Founded in the United States in 1976 as a materials research company, Oryx relocated to Fremont, California in 1991 to meet the growing needs for the advanced materials required to fuel the flourishing, transformative technologies of emergent Silicon Valley startups.

Continuous Innovation, Leveraging Opportunities

In 1999, Oryx Advanced Materials Sdn. Bhd. Was established in Penang, Malaysia as a wholly owned subsidiary of Oryx. The expansion was made to serve the growing demand for sputtering targets and bonding services for producers of hard disk drives (HDD) and components that are concentrated in Southeast Asia, Japan, Taiwan, and China.

HDD technology was developed by engineers working at IBM’s San Jose laboratory in California. The Oryx Fremont location was critical in participating in the development of new alloys that made digital storage possible and was integral in the development process of HDD.

In the 1990s, Southeast Asia – and Malaysia in particular – became the destination for the mass production of magnetic memory disks as HDD became the dominant digital storage solution. Selecting Malaysia for Oryx’s production facility enabled the MNC to benefit from the strong support and responsiveness of the Malaysian government.

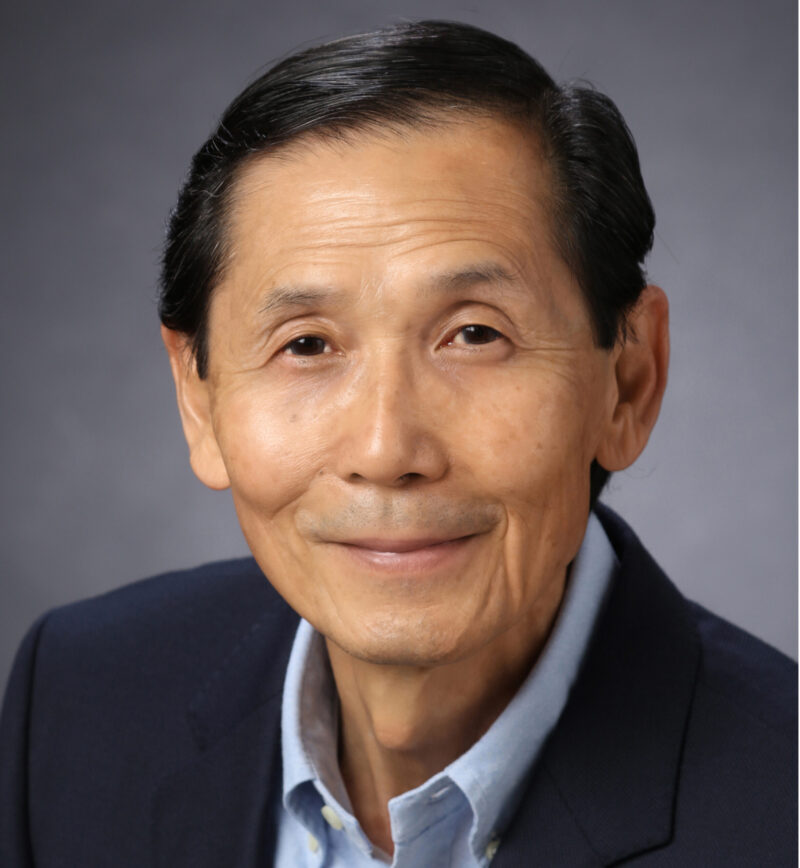

Oryx CEO, Victor Tan said, “Our entry into Malaysia in 1999 was well-timed with the surging disk drive industry in Southeast Asia. We began with a limited workforce focused on sputtering target bonding services.”

“In 2002 we began the transition to produce HDD sputtering targets, transferring the technology and adding additional square footage, installing the capability to make and clean the sputtering system shields and vacuum chamber parts while upgrading both the technology and manufacturing capabilities,” he recounted.

But the innovation did not stop there. In 2009, Oryx Malaysia entered the PV market and began producing sputtering target materials for this new and growing market, supporting multiple international companies that had chosen Malaysia for mass production of solar panels.

Oryx Advanced Materials Sdn Bhd – Penang, Malaysia

PV has since become a major business segment for Oryx and is expected to continue its dramatic growth and dominance as the go-to renewable energy (RE) technology across the globe.

Tan recalled, “We were fortunate to have the capability and knowledge to support the PV industry. Without MIDA’s support and encouragement, it would have been much more difficult to advance to our current technology leadership position.”

Photovoltaic Sputtering Targets

Continued Growth, Solid Government Support

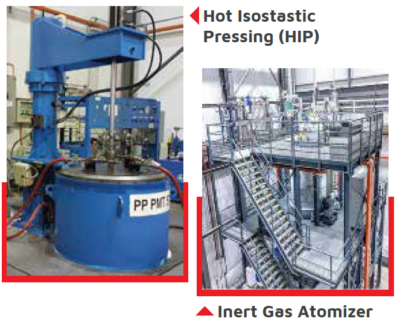

The Oryx Malaysia site in Penang now spans over 140,000 square feet and is staffed with more than 300 highly skilled technicians, engineers, and material scientist.

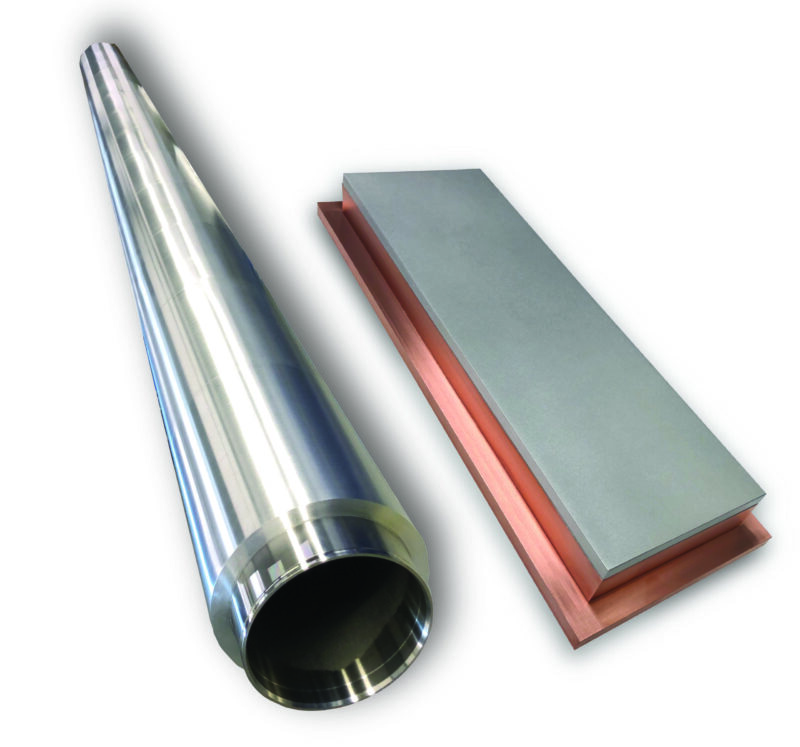

Tan said, “The company’s expertise in vacuum induction melting, inert gas atomisation, hot isostatic pressing, and material characterisation is unmatched in Malaysia and the surrounding countries. Significant growth is predicted as nations compete for these resources and services.”

Oryx has achieved the following certifications to service an existing and emerging customer base:

Tan noted, “We are now in the process of applying the experience, knowledge, and capability we have in metal alloy development to further the adoption and expansion of additive manufacturing.”

“Our goal is to be a cornerstone company for Malaysia and Southeast Asia for the developing technology of 3D printing with metal powders. We not only make the metal powder, but we also collaborate in developing the printing parameters, provide the post-processing capability such as hot isostatic pressing, and offer prototyping to verify design capability,” he added.

The company also focuses on “AM Ecosystem”, the ecosystem Oryx established to allow for Southeast Asia manufacturers to enter into the next generation of technology rapidly and seamlessly.

“The support from MIDA and Malaysia’s strategic importance to Southeast Asia’s growing economy have been key to our ability to grow our business in this part of the world,” Tan said.

When it came to selecting a viable country for Oryx’s ongoing growth and foreign investment, Malaysia was the premier choice. Its geographic proximity to customers in Japan, China, and Taiwan made relocation of the company’s large production facilities an obvious advantage, easily providing adequate space and enabling both swift communication and expedient material transfers.

The country was chosen for several economic factors in addition to its logistical superiority:

Continued Confidence in Malaysia

Oryx believes Malaysia continues to be an ideal location and one of the most convenient logistic and manufacturing hubs in Southeast Asia. “Oryx is committed to greater growth and prosperity with Malaysia and Southeast Asia as opportunities requiring material science “backbone” continue to multiply,” Tan said, adding that the company looks forward to a lengthy, beneficial relationship for years to come.

“We continue to invest and seek out new opportunities in Malaysia particularly in emerging technologies and the new markets they present,” he said.

For more information on how MIDA supports companies like Oryx Advanced Materials, visit MIDA’s website at www.mida.gov.my.

Source: MIDA e-Newsletter January 2022