This site

is mobile

responsive

Established in 1979, J.K. Wire Harness (JKWH) started from humble origins to support Malaysia’s then growing automotive industry. Today, JKWH has grown to become a key supplier to automotive assemblers and is the largest Malaysian automotive wire harness manufacturer in the country.

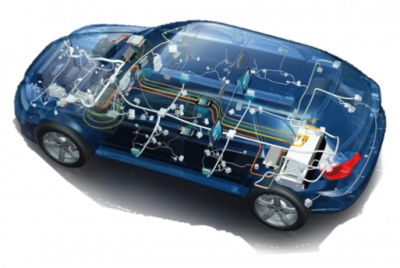

Wire harnesses function like the central nervous system of the human body. This assembly of electrical cables and wires is used to transmit signals and electrical power throughout a vehicle or machine. It is an essential component that affects performance, efficiency and safety.

Given the importance of wire harnesses and how it connects every key part of their customers’ products, JKWH provides design solutions to meet their needs of producing vehicles domestically while adhering to the Global Quality and Design standards that are expected of their brands. JKWH has local teams working together with its global technical partners to enable efficient communication and development of its products.

“…like the central nervous system of the human body, wire harnesses in a vehicle connect every part of the vehicle transmitting power and signals.”

JKWH has longstanding global partnerships with Sumitomo Wiring Systems, Ltd. of Japan, Kyungshin Co. Ltd. of Korea and Sumitomo Electric Bordnetze SE of Germany. These strategic alliances enhance the company’s capability to fully cater to the needs of its customers both at home and abroad, manufacturing products domestically at the highest international standards. The technical support and training based on Japanese, Korean and German automotive standards and developments ensure that JKWH consistently remains at the forefront of technological needs of the industry.

International partnerships going strong for over 40 years

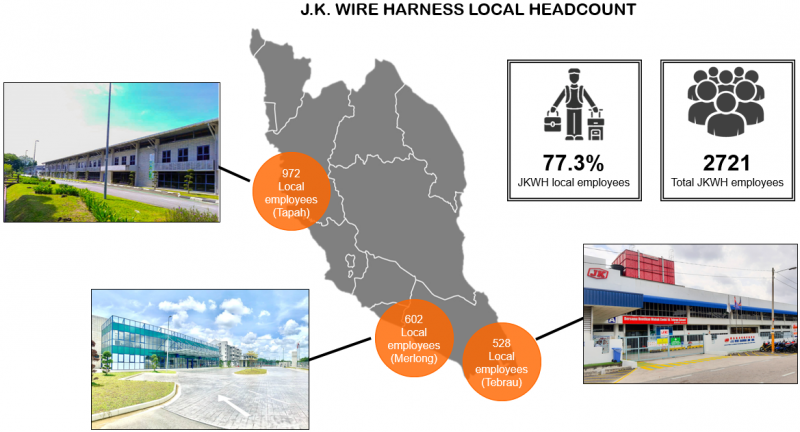

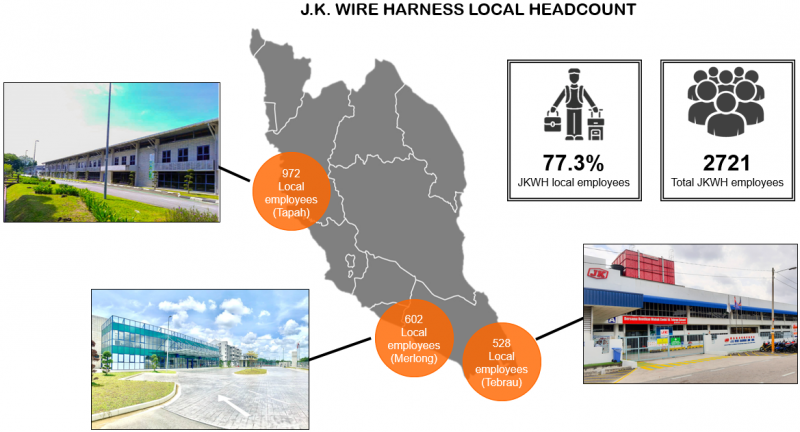

JKWH first started its operations in Johor Bahru more than 40 years ago. In the last 15 years with the assistance of local authorities, the company has expanded its manufacturing network to include production facilities in Merlong, Johor and Tapah, Perak. The communities at Merlong and Tapah have transitioned from agricultural to industrial economies with training and exposure to best practices in modern manufacturing and are now able to compete at the global level for quality, productivity and safety. Today, these two key locations provide a skilled and stable team of Malaysians for JKWH’s workforce, reducing the company’s reliance on foreign workers – inherently contributing to local job opportunities for the country’s growth and development.

JKWH continues to provide quality products at competitive prices, leveraging on its technical and financial strength, as well as best practices in corporate management, transparency and accountability. The company practices lean manufacturing and Kaizen which is the Japanese concept of ‘Continuous Improvement’ in all aspects of work at every level. The company’s unique blend of Malaysian and Japanese culture and continuous focus on improvement has won JKWH many awards throughout the years for Quality, Delivery and Excellence.

Source: JKWH (March 2021)

77 awards won in the last 25 years since 1996

As technology continues to evolve and vehicles continue to improve, the company has risen to the occasion with more sophisticated and complex products to meet the changing demands. To meet their customer’s requirements and maintain standards of excellence, JKWH also continues to invest in the latest technology and processes. Moving forward, JKWH seeks to remain as the leading wire harness manufacturer in Malaysia, operating at the forefront of global standards.

JKWH embraces Industry 4.0 and adopts the Industrial Internet of Things (IIoT) and smart manufacturing practices. The company is doubling its efforts towards achieving the status of a “Malaysian Smart Factory (MSF)” by the year 2024. Through collaborations with organisations such as the MIDA, the Malaysia Automotive Robotics and IoT Institute (MARii) and the Sustainable Energy Development Authority (SEDA), JKWH has several ongoing projects in various locations throughout Malaysia.

Such collaborations are instrumental to maintain their standards as a world-class manufacturing company. JKWH continues to invest time and effort to benchmark, evaluate and continuously upgrade its talents and processes. In addition, government support and facilitation, such as MIDA’s initiatives, have also contributed to their success over the years through training activities and exposure to the latest developments in technology.

Source: MIDA e-Newsletter June 2021

Explore other related content to further

explore MIDA’s insights.